As digital transformation deepens, enterprises are demanding more from their databases while data volumes surge. Many legacy stacks—including Greenplum—are increasingly strained. Large enterprises are therefore accelerating database upgrades and replacements.

This article presents an end-to-end anonymized case: how a leading domestic power-battery manufacturer migrated its core business data from Greenplum to YMatrix, covering decision-making, migration execution, and realized benefits.

As a top power-battery producer, the company has grown rapidly in recent years. Its batteries are widely adopted by global NEV (new-energy vehicle) makers, leading to high market share and large output. Consequently, the supply chain, production, and sales departments generate massive data every day. The original Greenplum cluster was increasingly overwhelmed.

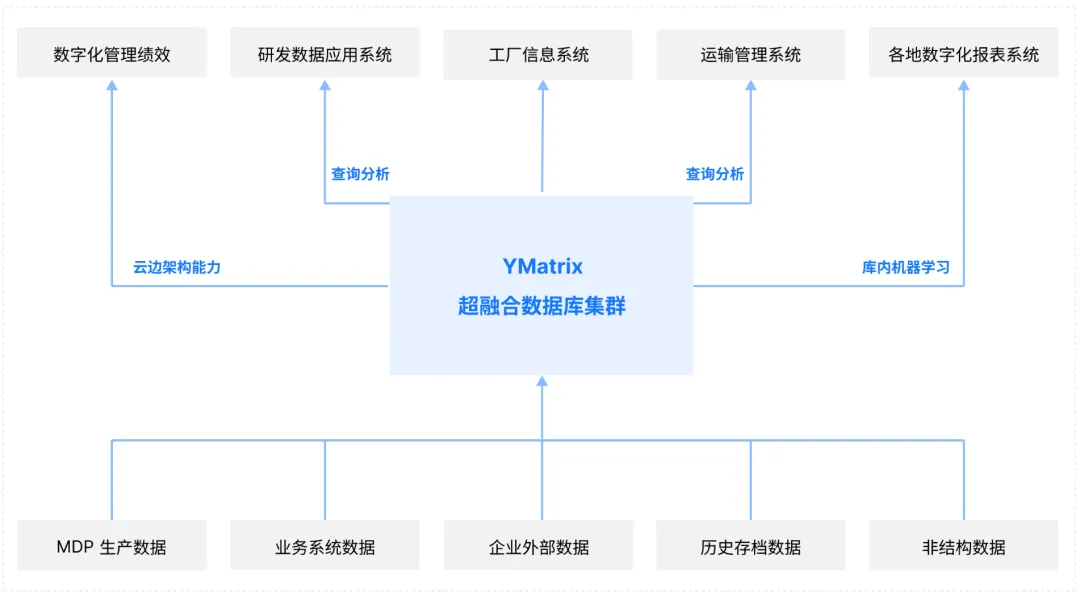

To relieve pressure on the legacy cluster and speed up decision-support reporting, the company decided to extract core business data from the sprawling database estate and build an independent enterprise big-data platform to consolidate data from all digital systems for analytics and decision-making. The platform now connects internal regional reports, R&D data, quality control, audit, plant information, facial recognition & access control, customer master, transportation management, process control, after-sales, and other core production/IT systems—providing unified interfaces for reporting. It has become one of the company’s most critical management-information systems.

With ongoing business expansion, more workloads were onboarded, driving up data volume and concurrency. Continuous streams of core data imposed stricter requirements on write and query performance. The legacy Greenplum cluster, limited in capacity, exhibited slower query execution as data and business grew, with occasional report unavailability, which began to impact normal operations.

The enterprise therefore needed to upgrade the big-data platform by replacing Greenplum with a higher-performance database to accelerate report generation and provide real-time decision support—while minimizing system changes to reduce migration risk. Another imperative was to reuse the existing tech stack and applications, avoiding major logic rewrites in upstream ingestion and downstream apps and ensuring a smooth business and technical transition.

After a thorough market evaluation, YMatrix initially stood out for strong analytical performance and converged product capabilities. In further tests using production data, YMatrix showed clear advantages in performance and features over the existing Greenplum cluster. The enterprise also ran TPC-H and TPC-DS benchmarks; results showed that in data-warehouse analytical scenarios, YMatrix performance exceeded Greenplum 6 by more than 4×.

YMatrix descends from Greenplum and is highly compatible with Greenplum functions and syntax, while significantly enhancing time-series writes/queries, multi-node high concurrency, and data compression, and providing a Chinese GUI for management—improving usability. This enabled smooth migration on both business and technical fronts and promised lower O&M costs going forward.

After careful assessment and testing, the battery manufacturer proceeded to migrate core business data from Greenplum to YMatrix.

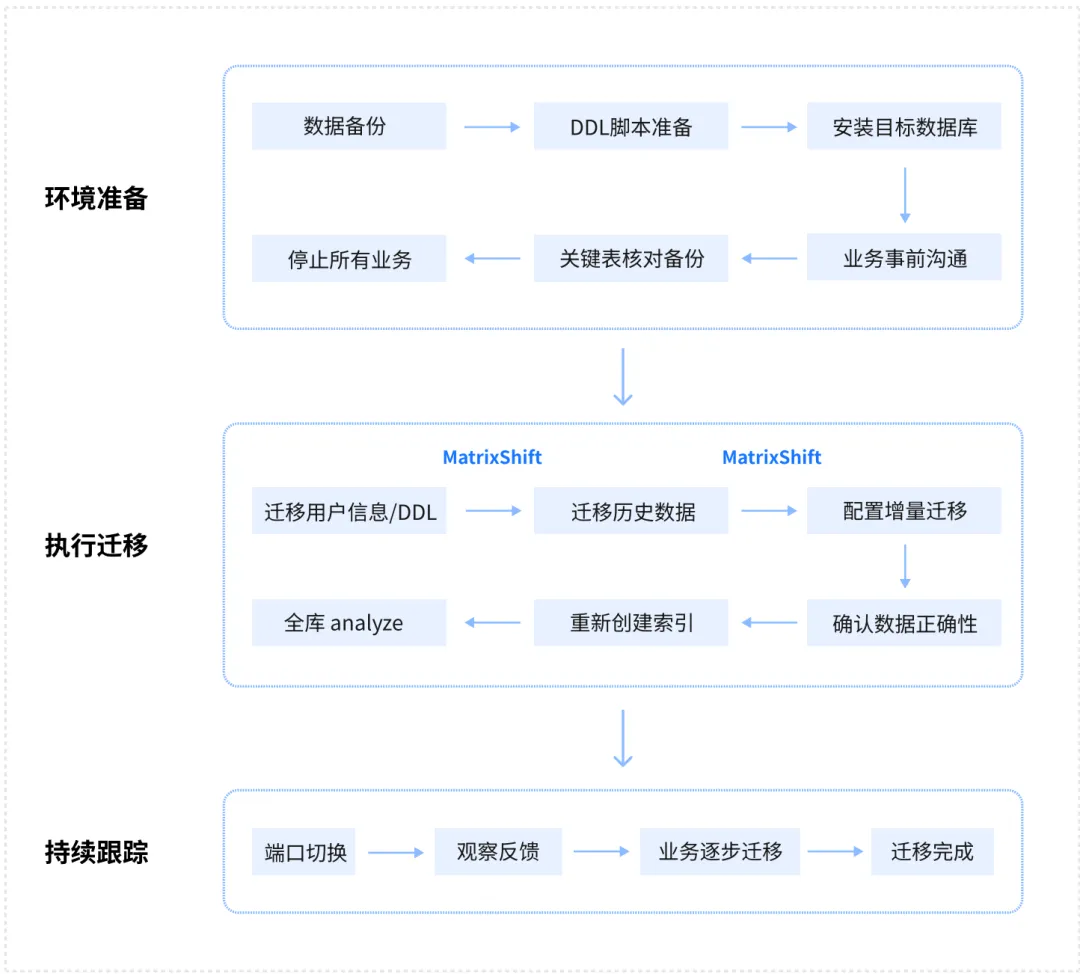

The migration covered full and partial incremental data, totaling around 20 TB, most of it core business data critical to decision-making. Thorough preparation was essential to minimize upstream/downstream impact:

Backup production data, extract detailed DDL and script it; prepare rollback plans to ensure rapid restoration in case of failure and mitigate business risk.

Prepare target-cluster software: install YMatrix, set up monitoring (e.g., Grafana), etc.

Align with business stakeholders on a change freeze during migration: no DDL on the business side (create/alter/add/drop fields); strictly prohibit CREATE/ALTER/TRUNCATE/DROP.

Per plan, convert two large tables into partitioned tables with 3-month cycles, verify them, then fully sync table data to the data-lake cluster for backup.

Stop non-critical platform workloads.

The newly developed migration tool MatrixShift played a key role.

As YMatrix’s full-database migration tool, MatrixShift supports full, incremental, and conditional migration, multiple data distribution strategies, table-level progress output, and real-time correctness checks—greatly improving the efficiency, safety, and automation of migration from Greenplum to YMatrix.

Steps included:

Use the MatrixUI graphical tool to initialize the YMatrix cluster; tune database/kernel/NIC parameters; enable resource groups.

Configure monitoring; use pg_dumpall to migrate user information and DDL.

Execute MatrixShift to parallelize full-data migration.

Because new data continued to arrive, incremental migration was required after the full load. To safeguard core business, cutovers were staged by business priority. After data migration, YMatrix and Greenplum ran in parallel for a period. Once validation passed, indexes were rebuilt on YMatrix and a cluster-wide ANALYZE refreshed statistics. Finally, the Greenplum cluster was shut down.

After migration, the YMatrix port was adjusted to match Greenplum’s so that existing apps could switch seamlessly. Business traffic was restored and observed. After 30 minutes with no anomalies in database logs or on the business side, write traffic was gradually resumed and monitored for several hours to ensure stability—thereby completing migration of the platform’s core data from Greenplum to YMatrix.

After moving to the YMatrix cluster, query performance improved by multiples versus before. Even as overall traffic and data volumes increased by an order of magnitude, the cluster remained stable and fully met business needs.

Having experienced YMatrix’s performance, compatibility with the existing stack, and a smooth, efficient migration, the battery manufacturer is planning to migrate more workloads to YMatrix to support new services and requirements and further enhance business agility.

Post-migration, the YMatrix cluster sits at the center of the big-data platform architecture—serving diverse upstream business needs and supporting downstream storage, consolidation, and unified management across multiple databases. As a hyper-converged database, YMatrix integrates structured and unstructured data in one system, supporting heterogeneous scenarios with a single database—which further reduces O&M costs.

To handle ongoing data growth, YMatrix supports online, smooth scale-out (reads/writes unaffected during expansion). Users remain unaware of changes, and the enterprise can expand on demand, giving the platform elastic headroom for future growth.

With high-performance writes, high-performance analytics, and high-concurrency queries, the distributed YMatrix cluster maximizes system resources for parallel query processing—unlocking peak cluster performance, significantly accelerating business queries, and sustaining the company’s core competitiveness.

Historically, some overseas commercial databases were first choices in finance, manufacturing, and other sectors. As businesses scale and digital transformation advances, demands on database performance and functionality have risen and diversified. Traditional databases can no longer meet ever-growing data needs, increasingly constraining enterprise development. Consequently, “upgrade” and “migration” now appear in more and more IT roadmaps.

In this project to migrate core data for a power-battery leader, YMatrix proved pivotal for both migration and performance improvement. The manufacturer will continue migrating legacy systems to YMatrix, broadening collaboration and building a more unified, efficient, group-level core data governance platform—so that data becomes a true advantage for future growth.

How YMatrix Helps Farasis Energy Achieve Smart-Factory Analytics in Seconds

SERES × YMatrix: 3-Hour Migration of 2.13TB, 50% Faster Multi-Scenario Queries

How YMatrix Domino Replaces Lambda, Kappa, Flink, and Spark with One Engine🚀

Ganfeng Lithium: Real-Time Reporting at Scale with YMatrix

YMatrix HTAP Transforms Month-End Closing for a 16,000-Store Pharma Chain

Smart Manufacturing at Scale with YMatrix HTAP: Real-Time Ingestion & Unified Analytics